Category 6e (Cat6e) wiring is an enhanced version of Cat6, offering higher bandwidth and faster data transfer rates, ideal for high-performance networks in homes, offices, and data centers.

Overview of Cat6e Wiring

Category 6e (Cat6e) wiring is an enhanced version of Cat6, designed for high-speed data transmission. It supports frequencies up to 500MHz and delivers faster data transfer rates, making it ideal for modern networks. Cat6e cables consist of four twisted pairs of copper wires enclosed in a protective jacket, minimizing interference. The wiring diagram typically follows T568A or T568B standards, ensuring proper connections. Its robust design and reliability make it suitable for home, commercial, and industrial applications, providing a scalable solution for demanding network environments.

Importance of Proper Cat6e Wiring

Proper Cat6e wiring is essential for ensuring reliable and high-speed data transmission. Incorrect installations can lead to signal interference, reduced performance, and connectivity issues. Accurate wiring ensures minimal signal loss and optimal data flow, crucial for networks requiring high bandwidth. Additionally, proper termination and adherence to standards like T568A or T568B prevent common errors, enhancing overall network efficiency and scalability. Proper wiring also minimizes the risk of cable damage and ensures compliance with industry standards, making it vital for both residential and commercial network setups.

Understanding the Cat6e Wiring Diagram

A Cat6e wiring diagram illustrates the layout and connections within the cable, ensuring proper alignment of the eight wires for accurate data transmission and minimal interference.

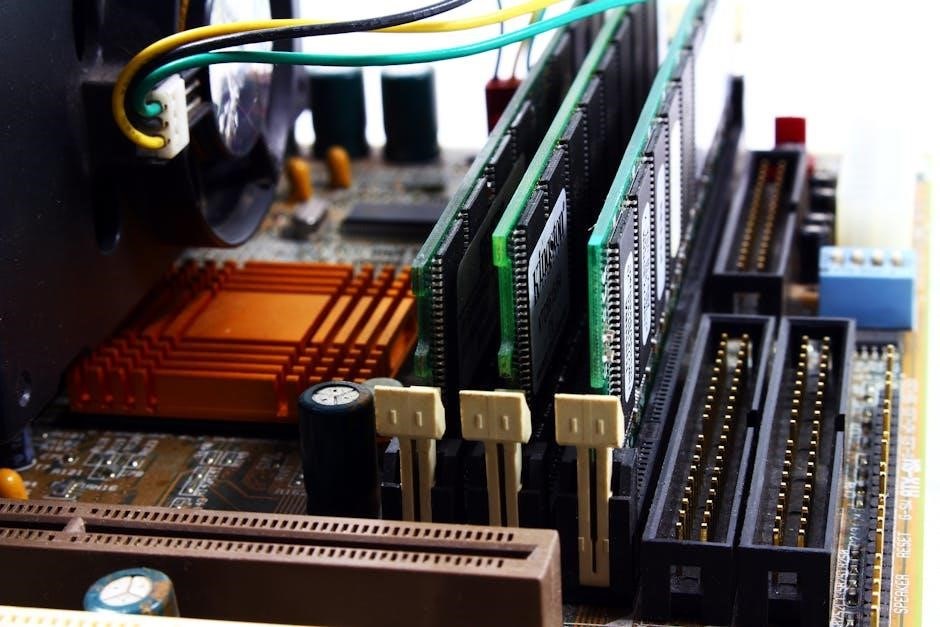

Structure of a Typical Cat6e Cable

A typical Cat6e cable consists of four twisted pairs of copper wires, each color-coded for easy identification. These pairs are encased in a protective jacket to minimize interference. The twisted design optimizes signal integrity, reducing electromagnetic interference (EMI) and crosstalk. Each wire is carefully arranged to maintain performance, ensuring reliable data transmission; The cable’s structure supports frequencies up to 500MHz, making it suitable for high-speed Ethernet connections. Proper handling and installation are crucial to preserve its performance capabilities and ensure longevity.

RJ45 Connectors and Their Role

RJ45 connectors are 8-pin modular connectors used to terminate Cat6e cables, enabling connections between devices like computers, routers, and switches. They play a crucial role in maintaining signal integrity by ensuring proper wire alignment. These connectors are used on both ends of the cable and are compatible with network interface cards (NICs) and Ethernet ports. Proper termination of the wires inside the RJ45 connector is essential to maintain the cable’s performance and support high-speed data transmission. Following T568A or T568B wiring standards ensures correct wire alignment and reliable network connections.

T568A and T568B Wiring Standards

T568A and T568B are the two most common wiring standards for Cat6e cables, defining the specific arrangement of the eight wires within RJ45 connectors. Both standards ensure proper data transmission but differ in the order of the wire pairs. T568B is more widely used in commercial settings, while T568A is often preferred in residential installations. The key difference lies in the color coding of the wires, with T568B swapping the positions of the green and orange pairs compared to T568A. Consistency in using the same standard at both ends of the cable is critical for optimal performance.

Tools and Materials Needed

Essential tools include RJ45 connectors, cable testers, wire cutters, and crimpers. Materials required are Cat6e cables, patch panels, and Ethernet sockets for a reliable network setup.

Essential Tools for Cat6e Wiring

Installing Cat6e wiring requires specific tools to ensure proper termination and connectivity. A high-quality cable tester is crucial for verifying wire continuity and detecting faults. Crimpers are used to securely attach RJ45 connectors to cable ends, while wire cutters and strippers handle cable preparation. A punch-down tool is necessary for connecting wires to patch panels and wall jacks. Additionally, cable organizers and labels help maintain a tidy installation. These tools are essential for achieving a reliable and high-performance network setup.

Materials Required for Installation

Installing Cat6e wiring requires several key materials to ensure a successful setup. High-quality Cat6e cables are essential for supporting high-speed data transmission. RJ45 connectors are needed for terminating the cables at both ends. Patch panels and wall plates provide structured connectivity points, while Ethernet switches or routers serve as the network backbone. Cable ties and labels help organize and manage the wiring. Additionally, faceplates, couplers, and punch-down tools may be necessary for certain installations. These materials ensure a reliable and efficient network infrastructure.

Step-by-Step Installation Guide

Install Cat6e wiring by cutting the cable to length, stripping insulation, arranging wires per T568A/B standards, terminating with RJ45 connectors, and connecting to network devices.

Preparing the Cat6e Cable

Begin by measuring and cutting the Cat6e cable to the desired length using cable cutters. Strip the outer jacket approximately 1.5 inches using a cable stripper, exposing the inner wires. Gently untwist the four pairs of wires, taking care not to damage the insulation. Arrange the wires according to the chosen wiring standard (T568A or T568B) for proper termination. Use cable ties to organize and secure the cable, ensuring minimal bending or twisting. This step ensures a clean and efficient installation process.

Stripping and Arranging the Wires

Using a cable stripper, carefully remove 1.5 inches of the outer jacket from the Cat6e cable. Gently untwist the four pairs of wires, taking care not to damage the insulation. Arrange the wires in the correct order according to the chosen wiring standard (T568A or T568B). Handle the wires by the insulation to avoid damage. Ensure the wires are straight and properly aligned before proceeding to termination. This step is critical for maintaining signal integrity and ensuring proper connectivity.

Terminating the Cable with an RJ45 Connector

Once the wires are properly arranged, carefully insert them into the RJ45 connector, ensuring each wire is seated correctly in its respective slot. Use a crimping tool to secure the connector, applying even pressure to ensure a tight connection. Verify that all wires are properly seated and the connector is securely attached. This step is crucial for maintaining signal integrity and ensuring reliable connectivity. Proper termination minimizes the risk of data loss and interference, ensuring optimal network performance.

Connecting the Cable to Network Devices

After terminating the Cat6e cable with an RJ45 connector, carefully plug it into the desired network device, such as a router, switch, or computer. Ensure the connection is secure to avoid loose links. Properly aligned wires and secure connections are essential for maintaining signal integrity. Always follow the T568A or T568B wiring standards for consistency. Once connected, test the link to confirm data transmission. A well-executed connection ensures reliable high-speed data transfer, supporting optimal network performance.

Termination and Connectivity

Proper termination techniques ensure reliable data transmission. Precise wire arrangement maintains signal integrity. Adherence to T568A or T568B standards guarantees compatibility. Thorough testing confirms optimal performance.

Proper Techniques for Wire Termination

Proper wire termination is crucial for maintaining signal integrity. Begin by stripping the cable to expose the inner wires, ensuring no damage occurs during this process. Next, untwist the pairs carefully to avoid introducing stress, which can lead to performance degradation. Arrange the wires according to the chosen T568A or T568B standard, aligning them correctly behind the RJ45 connector. Trim the excess wire close to the connector to prevent interference. Finally, crimp the connector firmly to secure the wires, ensuring a reliable connection. This meticulous process guarantees optimal data transmission and minimizes the risk of signal loss or interference.

Understanding Straight-Through vs. Crossover Wiring

Straight-through wiring is used for standard connections between devices, such as a computer to a router, where one end is configured as T568A and the other as T568B. Crossover wiring, in contrast, connects two similar devices directly, like computer-to-computer, by reversing the transmit and receive pairs. Both methods ensure proper communication, but their applications differ based on network setup. Understanding these configurations is essential for avoiding connectivity issues and ensuring optimal data transmission in various networking scenarios.

Testing the Connection for Integrity

Testing the connection for integrity ensures reliable data transmission and identifies potential issues. Use a cable tester to verify proper wiring according to T568A or T568B standards. Advanced testers can measure signal quality, detect wiring faults, and validate performance up to 500MHz. Regular testing helps maintain network stability, prevents connectivity problems, and ensures compliance with industry standards. This step is crucial for both new installations and existing networks to guarantee optimal performance and minimize downtime.

Best Practices for Installation

Best practices for Cat6e installation include proper handling to avoid damage, minimizing bends and twists, using the right tools, following T568A/B standards, and labeling cables for clarity.

Handling and Bending of Cables

Proper handling and bending of Cat6e cables are crucial to maintain their performance and longevity. Avoid tight bends, as they can cause signal loss or damage. Use cable ties or clips to secure cables without over-tightening, which can compress the wires. Keep bending radii above the minimum specified (typically 4 times the cable diameter) to prevent internal wire stress. Minimize twisting and kinking, as these can degrade signal quality. Store cables in a cool, dry environment, away from direct sunlight, and avoid excessive coiling. Handle cables gently during installation to prevent damage to the outer jacket and internal wiring. Proper bending and handling ensure reliable connectivity and maximize the cable’s lifespan.

Avoiding Common Installation Mistakes

To ensure a reliable Cat6e installation, avoid common mistakes such as improper wire stripping, incorrect connector type usage, and misalignment of wires during termination. Always follow T568A or T568B wiring standards strictly to prevent connectivity issues. Avoid over-tightening connectors, as this can damage the cable. Use the correct tools, such as a cable tester, to verify the integrity of the connections. Poor wire management, like leaving excess cable untidily, can lead to signal interference. Properly label cables to avoid confusion during troubleshooting. These precautions ensure optimal performance and minimize the risk of network disruptions.

Labeling and Organizing Cables

Properly labeling and organizing Cat6e cables is crucial for maintaining a tidy and efficient network setup. Use clear labels on both ends of the cable to indicate their purpose and destination. Color-coding can also help differentiate between various types of connections. Organize cables using cable ties, clips, or patch panels to prevent tangles and signal interference. Keep a documentation log of all cables and their connections for easy reference during troubleshooting or upgrades. This ensures a professional and scalable network infrastructure.

Troubleshooting Common Issues

Identify wiring errors, resolve connectivity problems, and use cable testers to verify signal integrity, ensuring reliable Cat6e network performance and addressing common installation challenges effectively.

Identifying Wiring Errors

Wiring errors in Cat6e installations can lead to connectivity issues and reduced performance. Common mistakes include incorrect wire arrangement, insufficient cable stripping, and improper RJ45 connector seating. To identify these errors, use a cable tester to verify wire continuity and detect opens, shorts, or miswired pairs. Ensure compliance with T568A or T568B standards, as deviations can cause signal degradation. Proper termination techniques and careful inspection of wire alignment are crucial to avoid errors. Addressing these issues promptly ensures reliable network performance and optimal data transmission speeds.

Resolving Connectivity Problems

Connectivity issues in Cat6e wiring can often be traced to improper termination, damaged cables, or environmental interference. Start by verifying all physical connections, ensuring RJ45 connectors are securely attached and cables are properly seated. Use a cable tester to identify faults such as opens, shorts, or miswiring. Check for damaged or bent wires, which can disrupt signal integrity. Environmental factors like electromagnetic interference or cable tension should also be evaluated. If issues persist, advanced testing tools like network analyzers can help pinpoint problems. Addressing these challenges promptly ensures reliable network performance and optimal data transmission.

Using Cable Testers for Verification

Cable testers are essential for verifying the integrity of Cat6e wiring installations. These tools detect issues like open circuits, short circuits, or miswiring, ensuring compliance with T568A or T568B standards. Basic testers can verify connectivity, while advanced models test for signal interference and cable length. Using a cable tester ensures reliable network performance by identifying faults early, preventing costly downtime. Regular testing with these devices is crucial for maintaining optimal data transmission speeds and signal quality in both residential and commercial network setups.

Applications of Cat6e Wiring

Cat6e wiring is widely used in home networks, commercial buildings, and data centers, supporting high-speed data transmission, reliable connectivity, and scalable network infrastructure for diverse applications.

Home Network Installation

Cat6e wiring is ideal for home network installations, providing reliable high-speed internet connectivity for streaming, gaming, and smart devices. Its enhanced bandwidth supports up to 10 Gigabits per second, ensuring seamless performance for multiple users and devices. By installing Cat6e cables, homeowners can create a robust and scalable network infrastructure that connects routers, modems, smart TVs, and computers. This setup minimizes signal interference and ensures a stable connection, making it perfect for modern home networking needs.

Commercial and Industrial Use Cases

Cat6e wiring is widely used in commercial and industrial settings to support high-bandwidth applications and ensure reliable network performance. In offices, it powers data centers, VoIP systems, and video conferencing tools. Industrial environments benefit from its durability and ability to handle large-scale operations, including factory automation and IoT devices. Cat6e’s enhanced performance and scalability make it ideal for businesses requiring fast and secure data transmission, ensuring minimal downtime and maximum productivity in demanding professional environments.

Data Center Applications

Cat6e wiring is crucial for data centers requiring high-speed, reliable connections. It supports up to 10Gbps, making it ideal for server connections, storage area networks (SANs), and cloud infrastructure. Data centers rely on Cat6e for its superior bandwidth and performance, ensuring minimal latency and maximum data integrity. Its durability and resistance to interference also make it a preferred choice for industrial-grade applications, where scalability and future-proofing are essential to meet growing demands in high-performance computing environments.

Performance and Optimization

Cat6e wiring supports up to 10Gbps and 500MHz bandwidth for optimal performance. Proper termination and cable management minimize interference, ensuring reliable and fast data transfer speeds in networks.

Maximizing Data Transfer Speeds

Cat6e wiring supports up to 10Gbps and 500MHz bandwidth, enabling fast and reliable data transfer. Proper termination, adhering to T568A or T568B standards, ensures optimal performance. Minimizing cable bends, avoiding excessive lengths, and using high-quality RJ45 connectors further enhance speed. Shielded cables can reduce interference in noisy environments. Regular testing with cable testers verifies integrity, ensuring maximum throughput. By following best practices, Cat6e installations deliver consistent high-speed connectivity, ideal for demanding networks in homes, offices, and data centers.

Minimizing Signal Interference

To minimize signal interference in Cat6e wiring, use shielded cables in noisy environments and maintain proper cable handling. Avoid bending cables excessively or routing them near power lines. Ensure tight twists in twisted pairs and use high-quality RJ45 connectors. Keep cables away from electromagnetic sources like motors or fluorescent lights. Proper termination and testing with cable testers help verify signal integrity. By following these practices, interference is reduced, ensuring reliable and high-speed data transmission across the network.

Optimizing Cable Length and Placement

Optimizing Cat6e cable length and placement is crucial for maintaining signal integrity. The maximum recommended cable length is 100 meters to prevent signal degradation. Avoid routing cables near power lines, motors, or fluorescent lights to minimize electromagnetic interference. Use cable ties or management systems to organize cables neatly, preventing damage and improving accessibility. Ensure bends do not exceed the minimum bend radius to avoid internal wire damage. Proper placement in both home and commercial settings ensures efficient performance and aesthetics, adhering to wiring standards for optimal network functionality.

Safety Precautions

Handle electrical components with care to avoid hazards. Prevent cable damage by avoiding improper bending or twisting. Ensure compliance with safety standards during installation and testing.

Handling Electrical Components Safely

When working with Cat6e wiring, always disconnect power sources before handling components to prevent electrical shocks. Use insulated tools to minimize risk of injury. Ground yourself properly to avoid static discharge, which can damage sensitive equipment. Ensure all connectors and cables are securely fastened to prevent accidental disconnections. Store electrical components in a dry, cool environment to maintain their integrity. Dispose of faulty or damaged components responsibly to prevent hazards. Follow manufacturer guidelines for safe handling practices to ensure reliability and performance of your network setup.

Preventing Damage to Cables

To prevent damage to Cat6e cables, avoid bending or twisting them excessively, as this can cause signal loss or internal wire damage. Use cable ties or clips to secure cables without over-tightening, which can strain the wires. Keep cables away from high-temperature sources, moisture, and direct sunlight to maintain their integrity. Use protective sleeves or conduit in high-traffic areas to shield against physical stress. Regularly inspect cables for signs of wear or damage and replace them promptly to ensure optimal network performance and reliability.

Ensuring Compliance with Standards

Ensuring compliance with standards is crucial for reliable Cat6e wiring. Adhere to established wiring standards like T568A and T568B for proper connector pin configurations. Use compatible RJ45 connectors and ensure cables meet Category 6e specifications. Proper termination techniques and cable testing are essential to verify data integrity. Always follow manufacturer guidelines and industry regulations to maintain consistency and quality. Compliance ensures optimal performance, supports future bandwidth demands, and guarantees a robust network infrastructure for years to come.

Proper Cat6e wiring ensures reliable, high-speed networks, supporting future demands. Adherence to standards and best practices guarantees optimal performance and minimizes connectivity issues for a robust infrastructure.

Cat6e wiring supports high-speed data transmission up to 10 Gbps, ideal for modern networks. Proper installation using T568A or T568B standards ensures reliability. Understanding cable structure, RJ45 connectors, and termination techniques is crucial. Testing connections with cable testers guarantees integrity. Best practices include avoiding excessive bending and labeling cables for organization. Adhering to safety protocols and using quality tools ensures optimal performance. This guide provides a comprehensive roadmap for successful Cat6e wiring, enabling efficient and durable network setups for homes, offices, and data centers.

Final Tips for Successful Installation

Always test the cable with a cable tester to ensure proper connectivity. Follow T568A or T568B standards consistently for accurate wiring. Handle cables gently to avoid damaging the twisted pairs. Plan cable routes carefully to minimize bending and stress. Label each cable clearly for easy identification. Store unused cables properly to prevent tangling. Regularly inspect cables for damage or wear. By adhering to these tips, you can ensure a reliable, high-performance network setup tailored to your needs.

Additional Resources

Explore recommended tools and suppliers for Cat6e wiring. Check out further reading and tutorials for advanced techniques and troubleshooting tips to enhance your installation skills.

Recommended Tools and Suppliers

For successful Cat6e wiring, invest in high-quality tools like cable testers, crimping tools, and wire strippers. Suppliers like Fluke, Panduit, and CommScope offer reliable equipment. Online retailers such as Amazon and eBay provide a wide range of tools and materials. Additionally, manufacturers like Belden and Siemon offer comprehensive resources and guides for Cat6e installations. Ensure you purchase from reputable sources to maintain performance and compliance with networking standards.

Further Reading and Tutorials

For in-depth learning, explore detailed Cat6e wiring guides and video tutorials available online. Websites like Fluke and Panduit offer comprehensive resources, while YouTube hosts step-by-step installation videos. Manufacturer guides from Belden and Siemon provide expert insights. Additionally, forums and tech communities share real-world experiences and troubleshooting tips. Check out tutorials on T568A and T568B standards, cable termination, and network testing. Visit Amazon or eBay for recommended tools and materials; These resources ensure you master Cat6e wiring for professional-grade network setups.